KISS Robotics

KISS Robotics

We specialize in developing and integrating robust robotic systems that

solve complex automation challenges. Whether you need to enhance

precision, improve system safety, or accelerate your development timeline,

our expertise in advanced robotics control and simulation provides a clear

path to success.

Please see our Testimonials page for

projects we successfully completed in the past.

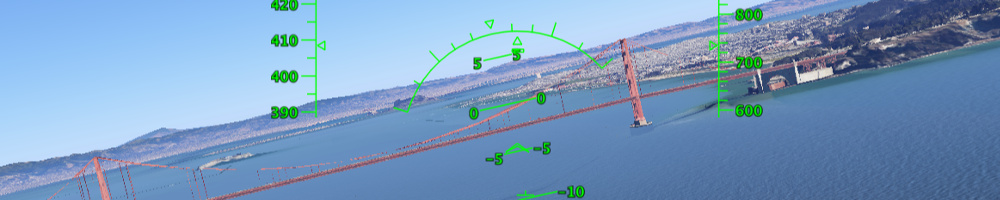

System integration

Especially in automation, there are always several subsystems which

need to work together seamlessly to achieve a common goal.

Good system integration is therefore essential for every successful project.

- Definition of component performance requirements and sourcing,

supplier Due Diligence:

Accelerate development and avoid costly mistakes

- Automated testing including Hardware-in-the-Loop: Speed up

testing by reducing manual steps

- Certification e.g. according to ISO-10218: Ensure that your

robot meets your customers' requirements

- Real-time buses including EtherCAT, CAN-Bus, UDP: Select

the right technology for your application

- Enforcement of hard realtime constraints on bare metal and embedded

Linux including Yocto, RedHat and Ubuntu: Avoid glitches and

enable safe and smooth operation

- Clean and safe APIs for humand and machine interaction:

Make it dead easy for your customers to use your product

and hence increase market traction

- IMUs and force/torque sensors: Enhance the awareness of your

robot of the physical world around it

Algorithms

Our advanced algorithms ensure your robotic systems operate with maximum

efficiency and safety. We move beyond basic programming to deliver

real customer value.

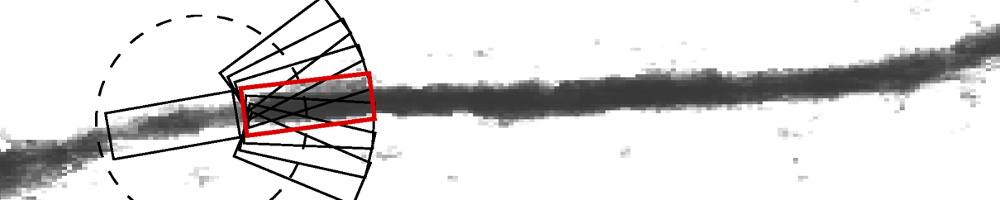

- Detection of self intersections and workspace violations:

For utmost operational safety and meeting ISO requirements

- Individual manipulator calibration: To enable sub-millimeter

absolute precision for highest production quality

- Modeling and simulation of robots and controllers:

To accelerate AI training, reduce physical prototyping cost and

shorten test cycles

- Automatic parameter identification: Accelerate

determination of essential robot parameters and make

the process more deterministic.

To achieve the above, we are experts in:

- Optimal Control

- Motion Planning (including AI integration)

- Obstacle avoidance

- Forward and Inverse Kinematics

- Jacobians and their applications

- Fast and accurate matrix and vector transforms

Controller tuning

For cobots and industrial robots, we do:

- Advanced full-body control: Enables the manipulator to achieve

complex tasks like cutting, welding etc.

- PID controllers with smart feedforward for high precision and minimal control

effort: Recude parasitic heat, energy consumption, and enable smooth

movement

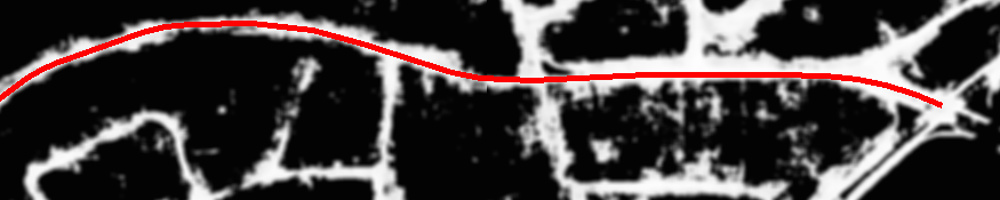

- Monitoring of safe position and velocity limits, workspaces,

self intersections and foreign objects: Avoid

collisions and accidents and make the robot safe to use even with humans around

it

- Gravity and friction compensation: Improve control response

and reduce energy consumption

- Force control for industrial applications and combined control:

Enable jobs that

require precisely defined forces, like polishing